Alodine is a chemical conversion coating applied to aluminum and its alloys. It enhances corrosion resistance and improves paint adhesion. Unlike other methods, it requires no electric current and maintains conductivity.

The process works by applying a chromate-based solution to clean metal surfaces. A chemical reaction forms a thin, protective layer that bonds directly to the aluminium. This layer resists corrosion and helps extend the part’s service life, especially in harsh environments.

Alodine coatings vary in colour and strength depending on the type. Type 1 creates a darker, heavier finish with greater protection. Type 3 forms a lighter, thinner coating ideal for parts that need painting. Both options maintain precise tolerances and are suitable for aerospace, military, and industrial use.

Alodine Surface

Alodine is a chromate formula-based chemical. It combines with aluminium to come up with a stable coating. This layer is in contact with the base material. It is not just a coating anymore; it becomes a part of their surface. The chromium used in the formula can be hexavalent or trivalent. Type is based on safety regulations or application.

Aluminium should be clean before treatment. Oxide has to be eliminated, as well as oil and dust. This is to give a homogeneous chemical reaction. Clean surfaces are made up of a stouter and even layer. The cleaning processes tend to be automated in industrial arrangements. This maintains consistency in all of the parts.

Alodine can be applied by spray, by brush, or by immersion. Selection is based on the size of parts and their volume of production. Spray is used on big or permanent objects. Immersion is suitable for large batches that are repeat parts. There should be strict control of time and temperature. This gives an even coverage and a good bonding.

The layer is fragile, but very effective. The common thickness is less than one micron. It is also good at guarding against moisture and oxidation. The finish will not peel and flake, or crack. It withstands heat or pressure. It is suitable as a base coat in case of harsh use.

Numerous industries exercise a high level of material compliance. Alodine is frequently used in military and aerospace. These are the MIL-DTL-5541 and ISO 8081. The UK and EU now constrain hexaoptions. Trivalent forms comply with the existing safety regulations. These produce the same outcomes with reduced risk to health.

Other steps are not blocked by Alodine. Coating can make it possible to paint, bond, or assemble. It is still possible to ground electronically on the surface. It does not affect fastener torque. The layer is vibration and heat-tolerant. This is vital when working in the aerospace or electronics field.

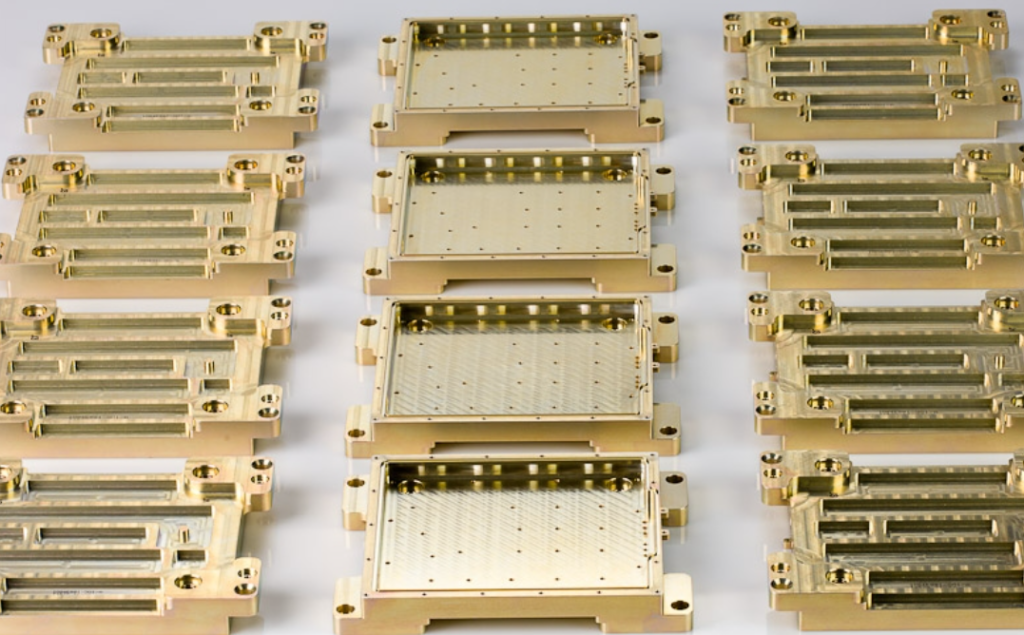

Alodine Coated Aeropsace Parts

Alodine is very common in aircraft parts. It shields structural panels, brackets, and housings. The coating does not add weight, but is resistant to corrosion. It also favors good adhesion of paint. Such qualities are crucial in assemblies that are flight-critical.

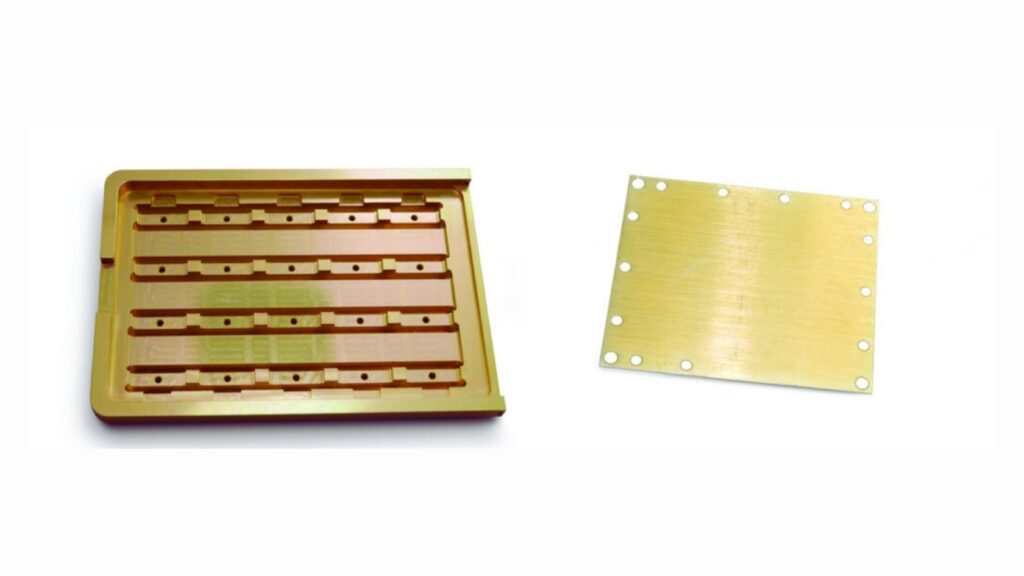

Alodine Coated Parts For Electrical Industry

The layer leaves aluminium conductive. This assists in grounding and EMI shielding. Before assembly, Alodine is used in many enclosures. It does not wear out through oxidation, and it promotes long-term dependability. Internal connections are not influenced in the process.

Alodine Coated Parts for Defence Industry

MIL-DTL-5541 coating is common to military parts. Alodine qualifies in terms of this standard with no struggles. It safeguards equipment to be utilized in rugged outdoor applications. It also deals with camouflage topcoats and coverings. The completion is field-certified and combat-ready.

Saltwater increases the rate of corrosion on unprotected aluminium. Alodine is a quick-acting barrier. It is applied frequently on the shipboard hardware and control panels. The finish is durable under extreme marine air with proper sealing. This adds to service life.

Alodine Coated Automotive Parts

Alodine is used in the chassis and engine parts by engineers. It cleans aluminium, ready to be painted or bonded. Some areas remain unpainted yet are not corroded. This assists in achieving durability objectives without bulk and costs.

Alodine Coated Electronics Products

Light enclosures must be both protective and conducting. Alodine takes care of these two issues altogether. It does not disturb contacts or shields. This finish is used on many avionics frames and brackets. It also manages vibration and heat.

Alodine is a conversion chemical process. It does not work on electrical current. Anodising is electrochemical and requires a source of power. These two treatments are similar in that both of them form oxide layers, but the process is different. The layer is formed by anodising with voltages and acid baths.

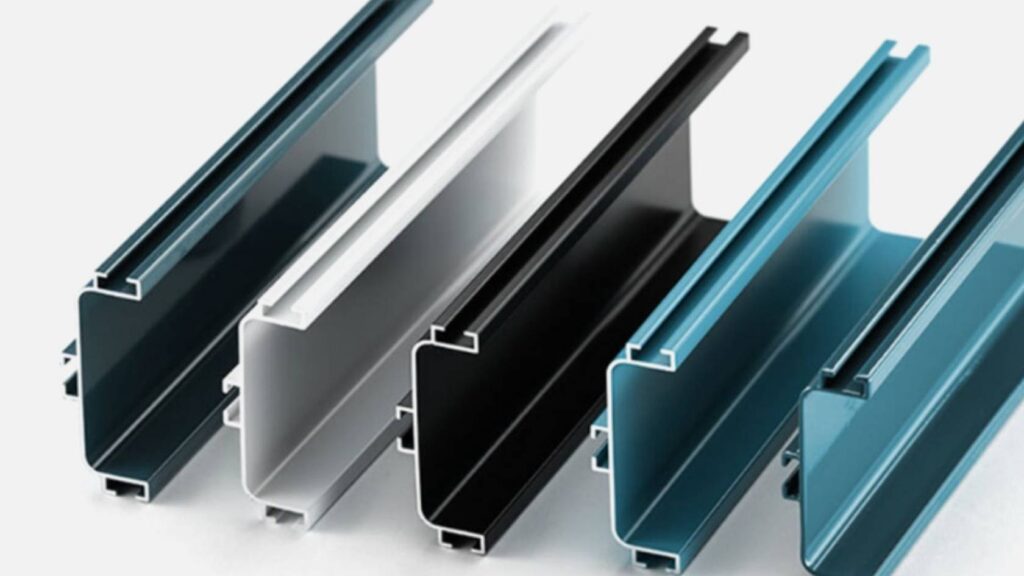

Aluminum Anodized Profiles

Alodine films are extremely thin. The majority are between zero point two and one micron. Anodised layers are thinner by many orders of magnitude, usually five to twenty-five microns. This also makes it better in terms of wear resistance and anodising. Alodine works well in cases where tolerances are important.

Alodine leaves the aluminium conductive. This is relevant to the grounding and EMI control. Anodised components turn out to be electrically insulating. Alodine can be used in case of conductivity required. Other engineers define the two processes concerning layered protection.

Both are resistant to corrosion; however, they do it in dissimilar manners. Alodine can be used in mild to moderate exposure. Anodising suits a harsh or outdoor environment. Anodising is more durable when it comes to high salt or chemical exposure. Alodine applies to parts installed indoors or coated parts.

Alodine is dull and matte. It could be either gold, green, or clear in type. Anodising is more colour and texture controlled. It is able to be dyed, polished, or etched. Anodise where the appearance is critical.

Alodine is less time-consuming and easier to use. It requires less equipment and fewer processes. Anodising is more time-consuming and requires more control. It is expensive per part, too. Use Alodine when time and low cost are more important than wear life.

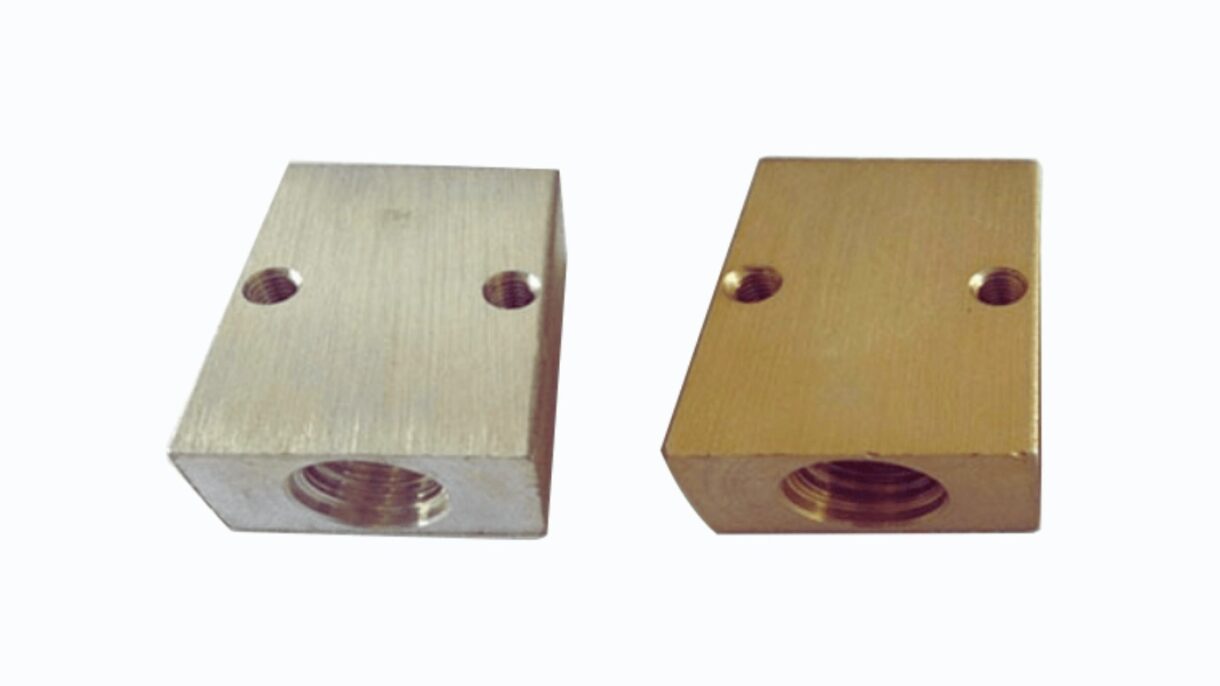

Aluminum Alodine Parts

Alodine has been specifically formulated to treat aluminium and aluminium alloys. It reacts well with the aerospace grades and industrial grades. The treatment makes a good union without causing damage to the base metal. This makes it corrosion-resistant and adherent.

It is mostly used on aluminium, but alodine can treat some non-ferrous metals. These are magnesium and some zinc alloys. Performance is not the same and has to be tested. Outside of aluminium applications, it is less common.

Alodine cannot be used on most ferrous materials. Steel and iron do not behave well with the chromate solution. Other forms of treatment include phosphating or galvanising, which are preferred. Always look at compatibility before specifying.

The application of Alodine must be done on bare metal. Parts painted or coated will not adhere well.l The coating is made to chemically change the metal surface. Components painted should first be Alodined and then painted/powder coated.

Alodine will not stick to plastics or composite materials. These must be prepared separately in terms of the surface preparation process. In the case of multi-material assemblies, metal parts should be treated before assembly. Avoid cross-contamination during the processing.

The alodine surfaces are compatible with the majority of industrial adhesives and sealants. The conversion layer enhances healthy bonding strength. Nevertheless, reference to compatibility is always essential with particular products. Certain sealants can use extra surface preparation.

Always start with a clean, dry surface. Remove oils, dirt, and oxides thoroughly. Use alkaline cleaning followed by rinsing. Proper prep ensures a consistent chemical reaction.

Alodine solution should be recreated or readjusted regularly. Maintain the level of chemicals within recommended limits. That prevents insufficient or uneven coatings, which diminish the protection.

Maintain the temperature of the solution between 20 and 30°C.. Soak items only as long as necessary,y which is about one to five minutes. No timing gives influence to coating thickness and quality.

Make a selection of the immersion batch. Big or involved parts are to be sprayed or brushed. To get the best of it, match your part size and production requirements to the method.

Cleaning parts with clean water should be done immediately after treatment. Dispose of all chemical residues to avoid contamination. Rinse and dry completely so as not to get any water spots or corrosion.

View coated parts with an even colour and finish. Perform the adhesion and corrosion tests as often as possible. Results of records to maintain the control of processes and quality improvement.

Uneven colour or splotchy spots are normally indicators of poor surface preparation. Check out cleaning procedures and make sure that all oil and oxides are cleaned. Check the concentration and time of application of chemicals also.

When paint or sealant adhesion is poor, the coating is either too thin or it is contaminated. Ensure that rinsing is done after treatment. Do not touch before painting or bonding.

alt: Steel Discoloration

Yellow or green stains may be left by overexposure or poor rinsing. Use super short immersion time and top-water quality. Dispose of fresh chemical baths on a routine basis.

Flaking is a sign of contamination or loss of bonding. Cleaning of review surfaces survey. Make sure that the Alodine solution is in specification and uniformly apply the coating.

In case of the rapid degradation of chemical baths, overuse or contamination is expected. Put in place regular inspection and screening of baths. Educate the employees about handling and disposing of chemicals.

Poor quality of the spray nozzles, thermostats, or clocks is observed. Set up regular maintenance and calibration. Maintain spare pieces of major equipment to eliminate downtimes.

Examine the components on a routine basis to identify corrosion and breakage. Be careful of ripples or peels or blotches. The damage is detected early,y and can also avoid repairs that cost a lot.

Washing is done using soft soaps and towels. Do not use rough chemicals or abrasive materials that will hurt the coating. Dry and tidy.

On Alodine, test the adhesive value of paint or sealant. Poor adhesion can be a sign of improper coating, imperfection, or contamination. Repeat post-therapy.

Take a corrosion test periodically, and particularly in hostile environments. The coating durability is presented by salt spray or humidity tests. Maintain the plans through results.

The spot treatments can fix minor damages. Clean, again apply Alodine and leave to cure. When the damage is bigger, then think of complete re-treatment or replacement.

Write down inspection, cleaning, and repair. This assists in monitoring part condition over time. To enhance maintenance planning and management of the processes, use records.

A thin protective layer is provided by Alodine. The layer inhibits the oxidation of aluminium. It increases the life span of components in numerous settings.

The coating does not reduce the electrical conductivity of the metal. This is necessitated in grounding and EMI shielding. It aids the aerospace and electronic applications.

Alodine increases the adhesion of paints and primers. This provides longer-lasting finishes. It minimizes the chances of developing peeling or flaking.

It is quicker and cheaper than anodising. It uses less and less complicated equipment and energy. This reduces the costs and time of production.

Alodine does not cause much weight addition to parts. This is why it is appealing to aerospace and automotive parts. It secures without performance impact.

The process is appropriate for different sizes and shapes of parts. It can be operated using sprays, brushes, or immersion. This adaptability is in accordance with various production requirements.

Alodine coatings are so thin that and can wear off. They provide low resistance to abrasion and mechanical hazards. The areas that are exposed to extreme wear can require additional protection.

Hexavalent chromium is present in some Alodine. It is a toxic chemical that is prone to strict regulations. There are safer options, which can be expensive.

Alodine only gives dull matte finishes. It does not have the decorative colour choices that are possible with anodising. This restricts applications where good looks are a priority.

Perfectly clean surfaces are necessary in the coating. Oil, dirt, and oxide will decrease effectiveness. Poor adhesive and corrosion coatings are caused by uneven preparation.

Alodine is used primarily on aluminium and certain alloys. It has a poor performance on steel and other ferrous metals. These materials need other treatments.

The conversion layer is thin and typically less than one micron. It fails to offer the thickness required to be used in heavy-duty corrosion or wear protection.

Each type of Alodine applies to different applications. The trivalent formulations are less harmful to the environment, but they might need more stringent controls. Select a formula that is performance, cost, and compliance balancing.

Apply specially designed cleaning methods based on both the alloy and the kind of contamination. In case of heavily soiled areas, use alkaline cleaners. Stubborn oxides should be deoxidised. Good preparation reduces defects and enhances the adhesion of the coating.

The process of automation increases uniformity and throughput. Automated spray/immersion lines ensure controlled exposure to chemicals and reduced man-made error. It is very important in mass manufacturing and for strict tolerance.

Add a camera or sensor-based inspection in real-time. Monitoring the colour fluctuations or irregularities on the surface in real time. The upshot is that early detection reduces the costs of rewinding and enhances the overall quality.

Adhesive as a primer beneath paints or under powder coating. It strengthens adherence and corrosion. Pay attention to compatibility to prevent unwanted chemical reactions.

Anodizing produces a tough, hard oxide coating on aluminium. It possesses better corrosion and wear resistance. It also gives a decorative coating with different colour choices. Nonetheless, it is more time and equipment-consuming than Alodine.

The classical chromate coatings have very good corrosion resistance. Hexavalent chromate is very efficacious and dangerous, and strictly regulated. Trivalent chromate is safer, and competes in performance with comparable applications.

Phosphating is the deposition of phosphate crystals on metal. It enhances anticorrosion and paint adhesion. Phosphating is applied to steel, but can be applied to aluminium in special formulations.

These are protective coatings against corrosion. They come in numerous formulations that target certain surroundings. They need to be properly prepared on the surface and, in some cases, a conversion coating beneath to work out well.

Powder coating is the application of dry powder, including electrostatic curing. It makes a hard, wear-resistant finish that is corrosion-resistant. With powder coating, the colours and textures available are numerous, and it requires a well-prepared surface.

Silane coatings are chemically bonded to a metal surface and form a corrosion-resistant layer. They are eco-friendly and do not contain heavy metals. These are called silane treatments and are often applied instead of a primer before painting or sealing.

Choosing Alodine depends on your project’s specific needs. If you require fast, cost-effective corrosion protection on aluminium parts, Alodine is a strong candidate. It offers good corrosion resistance and excellent paint adhesion without adding significant weight.

However, if your project demands high durability or decorative finishes, Alodine may fall short. Its thin coating wears quickly under mechanical stress and has limited colour options.

Consider environmental regulations, too. Some Alodine types contain hazardous chemicals that might not comply with your local standards. Safer trivalent alternatives or other surface treatments could be better.

Apexrapid offers expert Alodine treatment for aluminium parts. Our process ensures consistent corrosion protection and improved paint adhesion. We use industry-approved chemicals and strict quality control to deliver reliable results.

Whether you need batch or custom treatment, Apexrapid adapts to your production scale. Our skilled technicians handle surface preparation and application with precision. We also ensure compliance with environmental and safety standards.

Choose Apexrapid for fast turnaround times and competitive pricing. Protect your aluminium components effectively with our trusted Alodine services.