Heat treatment is an indispensable method used to change the structure of metals. It plays a critical role in precision manufacturing. It allows metals to perform under pressure, load, and thermal variation.

In medical production, heat treatment ensures surgical-grade alloys resist fatigue and maintain form during repeated sterilisation. It supports fine machining by stabilizing the structure before cutting or shaping. This reduces part distortion and tool wear.

In aerospace and defence, parts face constant vibration, heat, and impact. Heat treatment strengthens alloys without adding weight. It also prevents grain shift that can cause cracking during flight or high-altitude expansion.

In energy systems, treated metals handle thermal cycling inside turbines and reactors. This keeps seals, fasteners, and blades stable across long service cycles. The result is lower maintenance and greater operational uptime.

By refining grain size and removing internal stresses, heat treatment brings predictable strength. This allows complex components to meet strict inspection standards and perform consistently over time.

Performance improvement of metal involves heat treatment to change the microstructure. Every process involves specific heating and cooling processes. This alters hardness, strength, ductility, and toughness. The following are ten major methods with a technical insight.

Annealing is done by heating metal to above its recrystallisation temperature. This is then gradually cooled, most often in a furnace. This gives room for new strain-free grains to develop. Previous work stresses are done away with. The metal will become soft and ductile. Machinability is increased, and the risks of cracking during forming are decreased with annealing.

Normalising heats steel in a temperature above the critical temperature, which is about 850 °C. It is cooled naturally in air, and it is quicker than annealing. This gives a more refined and even grain structure. The effect is the gain in tensile strength and hardness. The toughness of normalised steel also increases, and the mechanical uniformity of the piece is improved.

In quenching, steel is heated to the austenitising temperature, i.e., 800-900 C. These metals are cooled quickly by the use of water, oil, or polymer solutions. This locks the carbon atoms in an abnormal lattice, which constitutes martensite. Martensite is a very brittle phase; it is very hard. Tremendously, quenching enhances hardness, but it induces residual stresses and brittleness.

Quenching is then followed by tempering, which is done by reheating the metal to a temperature range of between 150 and 650 degrees Celsius. This lets the carbon atoms diffuse out of martensite. It lowers its internal stresses, and some ductility is regained. The metal is able to retain strength, but also loses brittleness. To balance the hardness and the toughness, the times and the temperatures of tempering are modified.

The process of stress relieving involves heating up metal below the temperature of its critical transformation, which is usually about 500 degrees Celsius to 650 degrees Celsius. The heat causes atoms to move a little and removes any leftover tensions on welding, casting, or machining. Hoisting does not significantly alter hardness, but the dimensional stability of the material improves, and the risk of distortion during later use is reduced.

A solid solution is obtained through solution treatment of alloys (e.g., aluminium and titanium). The metal is heated to the desired temperature and kept at that temperature for a determined period of time, and then is quenched quickly to entrap the elements homogeneously. This forms a supersaturated solid solution. It gets the alloy ready to be hardened by aging later, and when that happens, fine precipitates can form, giving it greater strength.

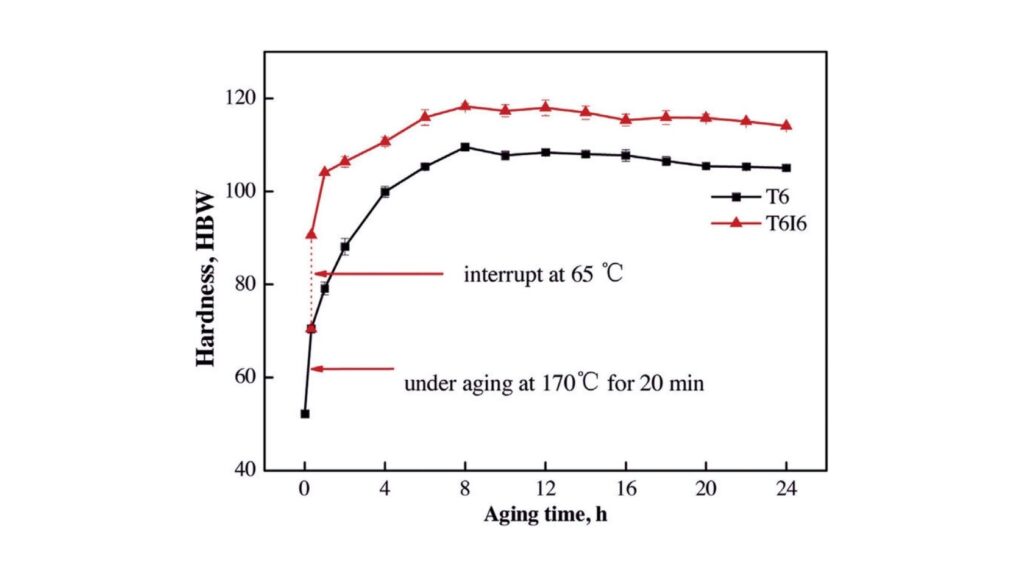

Age hardening is also referred to as precipitation hardening and is a process that comes after solution treating. The metal is again re-heated to a lower temperature, which is about 150-200 degrees Celsius. The precipitates that are very fine are formed during this stage within the grains of the metal. These precipitates hinder the flow of dislocations, and in the long run, the result of strengthening and hardening is enhanced. It is a time sequential process, which can last hours or days.

Carburizing involves inserting carbon into the shallow surface of low-carbon steels. This is achieved through heating the metal in a carbon-rich enough atmosphere with an approximate temperature of 900 degrees Celsius. A case of high carbon is formed when carbon atoms diffuse into the surface. Upon quenching, the surface is hard and wear-resistant, and the core is tough and ductile. This is perfect for gears and shafts where durability is required on the surface and strength is required at the core.

Nitriding inserts nitrogen atoms into the steel surface at a temperature of 480 to 550 degrees Celsius. It also creates hard nitrides in the surface layers of the metal. Nitriding does not need quenching, unlike carburising, so distortion is minimised. The outcome is a wear, hard, and corrosion-resistant surface that is well suited to precision tools and stainless steels.

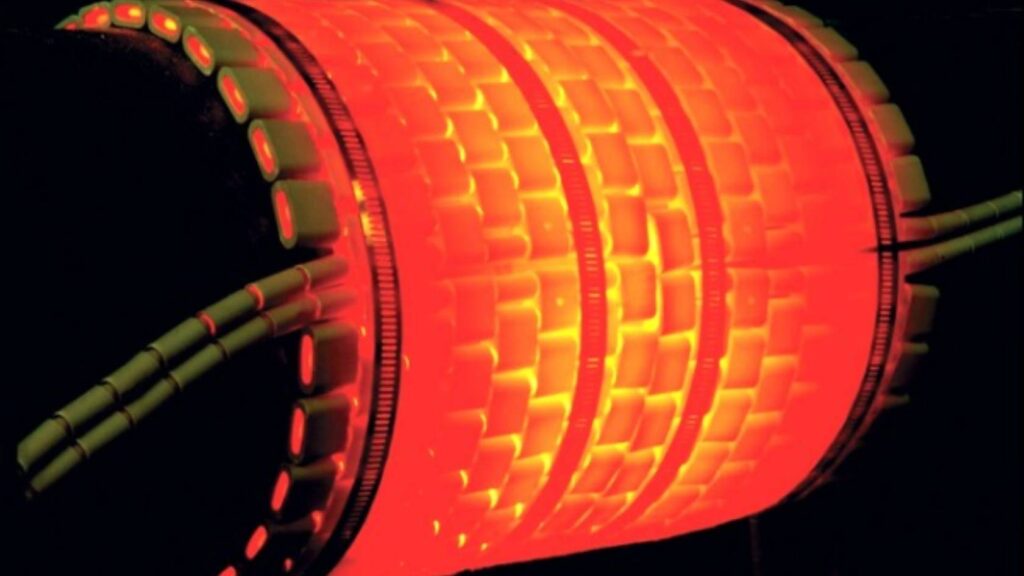

Induction hardening is a process in which electromagnetic induction is used to heat the desired locations on a metal piece quickly. The surface is taken to the austenitising temperature in seconds. Then it is rapidly quenched to produce martensite just in hot areas. The effect of this is the creation of a hard, wear-resistant surface, and the core is tough. Induction hardening is accurate and time-saving in the treatment of gears, camshafts, and bearing races.

The successful heat treatment is highly dependent on numerous factors. These have to be regulated in order to obtain the desirable metal properties. The following are some of the main factors that affect the process and outcome.

The composition of an alloy determines how the alloy will react to heat treatment. Such elements as carbon, chromium, and nickel alter hardenability and transformation temperatures of the phases. To select an adequate heat treatment method, you have to be aware of the properties of the alloy.

Heating must be precise in temperature control. Overheating or underheating beyond the right optimal range may lead to undesired phases or grain growth. Unified temperature provides a consistent treatment of the entire part with no weak areas.

The exposure to temperature influences microstructure alterations. A hold that is too short will not transform the metal completely, whereas too long will result in grain coarsening. The right timing is a balance between total change and staying strong and tough.

The rate of cooling of the metal also determines final hardness and ductility. The quick cooling forms hard, brittle phases. Slow cooling increases toughness at the cost of hardness. The selection of the cooling medium is also very important in attaining the desired results.

The quality of surface preparation and cleanliness affects the quality of heat treatment. The heat transfer may be hampered by scale or contaminants and lead to unequal treatment. The correct cleaning and surface finishing will provide even reactions and properties.

Complex parts or thicker parts do not heat and cool uniformly. This may create internal stress or distortion. More time is required to heat the part and to cool it down with precision to provide a uniform treatment within the part volume.

Optimising heat treatment requires careful control of many variables. Follow these tips to ensure consistent, high-quality results for your parts.

Keep the temperature precise by using calibrated sensors. The slightest variations will change the properties of metals. Always remember to keep up with the accuracy and ability to make the furnace uniform. This avoids malfunctions and imbalanced treatment.

Pay attention to monitor holding times cycle by cycle. Incomplete transformation is a result of underheating. Grain growth and metal weakening are brought about by overheating. Automated timers can be used to eliminate errors.

The choice of cooling techniques depends on alloy and geometry. Quick cooling will toughen steel, but it is liable to crack. Staged cooling or agitated cooling may be required on complex shapes. Make sure you find the balance between being hard and tough.

Heat treatment requires clean parts. Clear oils, dirt, and scale interfere with the heat transfer is interfered with. Homogeneous temperature and reaction are achieved by a clean surface. This increases final quality and evenness.

If the protective gases are needed, use nitrogen or argon. This prevents oxidation and decarburisation during the heating. Part of life and appearance are prolonged by controlling the atmosphere.

Thick or complex parts can be adjusted to heating and cooling times. The bigger pieces require more soak time to spread even heat. Internal stresses and distortion can be avoided through controlled cooling.

The defects may arise as a result of heat treatment unless carried out properly. Learning about these issues can help you avoid the expensive mistakes. The following are some of the common defects and how they can be avoided.

Warping is a consequence of improper heating or cooling that results in internal stresses. There is a change of shape or size of parts, and this influences tolerances. This can be avoided by controlling heating rates and slow and uniform cooling of thick or complex parts.

This can lead to cracks because of fast cooling or too much stress internally. Another problem with quenching that is not accompanied by tempering is brittle structures that crack easily. To enhance toughness, use cooling and quenched tempering of parts.

Decarburisation is the loss of surface carbon under heating in the open air. It reduces wear resistance and hardness on surfaces. Avoid it when heat treatment is done with protective atmospheres or coatings.

Grain growth is the result of overheating, which makes the material weaker and less tough. It raises oxidation and scaling as well. Care should be taken to check the temperature, and holding time should be minimal to avoid overheating.

Scaling occurs when metal is exposed to high temperatures in the presence of oxygen and forms surface oxides. This may influence the appearance and the finish. Reduction of scaling should be done by using controlled atmospheres or coatings.

Partial change happens when the metal is not kept long enough at the desired temperature. This causes irregular mechanical properties. Make sure that there is a proper holding time and temperature to get complete phase changes.

This choice of equipment will guarantee effective and accurate heat treatment. New technology increases control of the processes and uniformity. Major types of equipment and their functions are presented below.

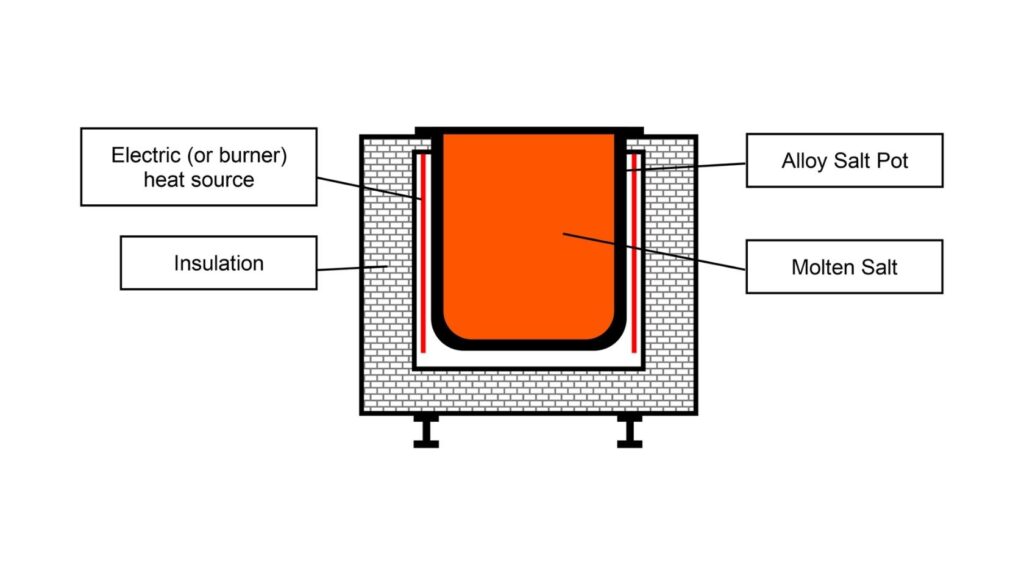

Metal parts are heated in a controlled manner by furnaces. They are of different kinds, e.g., batch, continuous, and vacuum. It should be capable of precise regulation of temperature as well as uniform distribution of heat.

Temperature within furnaces is governed by such sensors as thermocouples. The heating elements also have controllers to reach setpoints. The proper sensing and control eliminate overheating and underheating.

The parts are cooled down very fast by quenching equipment with water or oil, or polymer solutions. Climatic systems are automated to provide uniform cooling. The effect of proper quenching is that distortion is minimized and hardness is controlled.

Such systems control gases in furnaces to avoid oxidation and decarburisation. They can employ endothermic gas mixtures, argon or nitrogen. Controlled atmospheres lead to better quality of the surface and material characteristics.

In modern equipment, software programs, cycles, and charts are used in the heat treatment. Automation enhances repeatability and minimises the existence of human error. The real-time monitoring can make adjustments quickly.

Heat treatment results are checked using equipment such as hardness testers, microscopes, and non-destructive testing machines. By incorporating test tools, feedback is instant, and quality is guaranteed.

It is important to control the costs of heat treatment so as to make no compromise to quality. These are the strategies that you can implement in order to optimise your budget and production efficiency.

Determine the most efficient batch sizes to make the most use of the furnace by limiting downtime. Larger batches, properly organised, reduce energy consumption and have higher throughput.

Combine a few processes, such as annealing and tempering, into one furnace cycle. This minimizes handling, cycle time, and labour costs.

Invest in furnaces that are more insulated and that are more controlled. The energy-efficient models use less fuel or electricity and lower the operating expenses.

Eliminate unwarranted steps and a reduction in downtime. Automated workflows cut down on waste and increase turnaround, all without affecting quality.

Use reused oils or use polymers in quenching tanks. Recycling helps cut down on material prices and disposal expenditure on the environment.

Train your employees in effective ways. Experienced operators avoid mistakes that result in rework and wastage of energy.

There are cases when the traditional heat treatment does not fit your project. The search for new approaches would help to increase efficiency, as well as the quality of parts, and address particular demands.

Addition of hardness and wear resistance by coating, like physical vapour deposition or thermal spray, is done. The techniques modify the surface characteristics but do not modify the microstructure of the whole portion.

This is a process where the parts are cooled down to very low temperatures in order to change the retained austenite to martensite. It improves the dimensional stability, wear, and fatigue life, particularly in tool steels.

Laser heating is used to harden surfaces in a particular area. It enables flexibility of control, low distortion, and high throughput. This is perfect for those parts that need selective hardening and have confined tolerances.

Carbon or nitrogen is introduced into the top layer through these thermochemical processes. They form wear-resistant, hard cases and also preserve a tough core, and they are applicable on shafts and gears.

Induction heating is a quick method of heating metal surfaces with the aid of electromagnetic fields and quenching. It gives fast, energy-saving hardening with minimal thermal distortion.

The Powder metallurgy produces components that have custom microstructures and features. It usually removes or minimizes the necessity of lengthy heating processes by regulating the composition and density of materials during the initial stages.

Heat treatment helps make metal parts stronger and last longer. But there are other ways to improve parts, too. Choosing the right method depends on what the part needs to do and the materials used. When you pick the right process, you save time, cut costs, and get better results. It’s all about finding the best fit for your project.

Q1: How do I know which heat treatment method suits my part?

A: Look at the material, size, and what performance you need. Talk to experts to find the best match for your part’s function.

Q2: Can I use alternatives to heat treatment for all metals?

A: Not all metals respond the same way. Some alternatives work well for specific alloys or parts, so it’s important to check compatibility.

Q3: What is the most common cause of heat treatment problems?

A: Often, uneven heating or cooling causes issues like warping or cracking. Proper process control and monitoring prevent these problems.